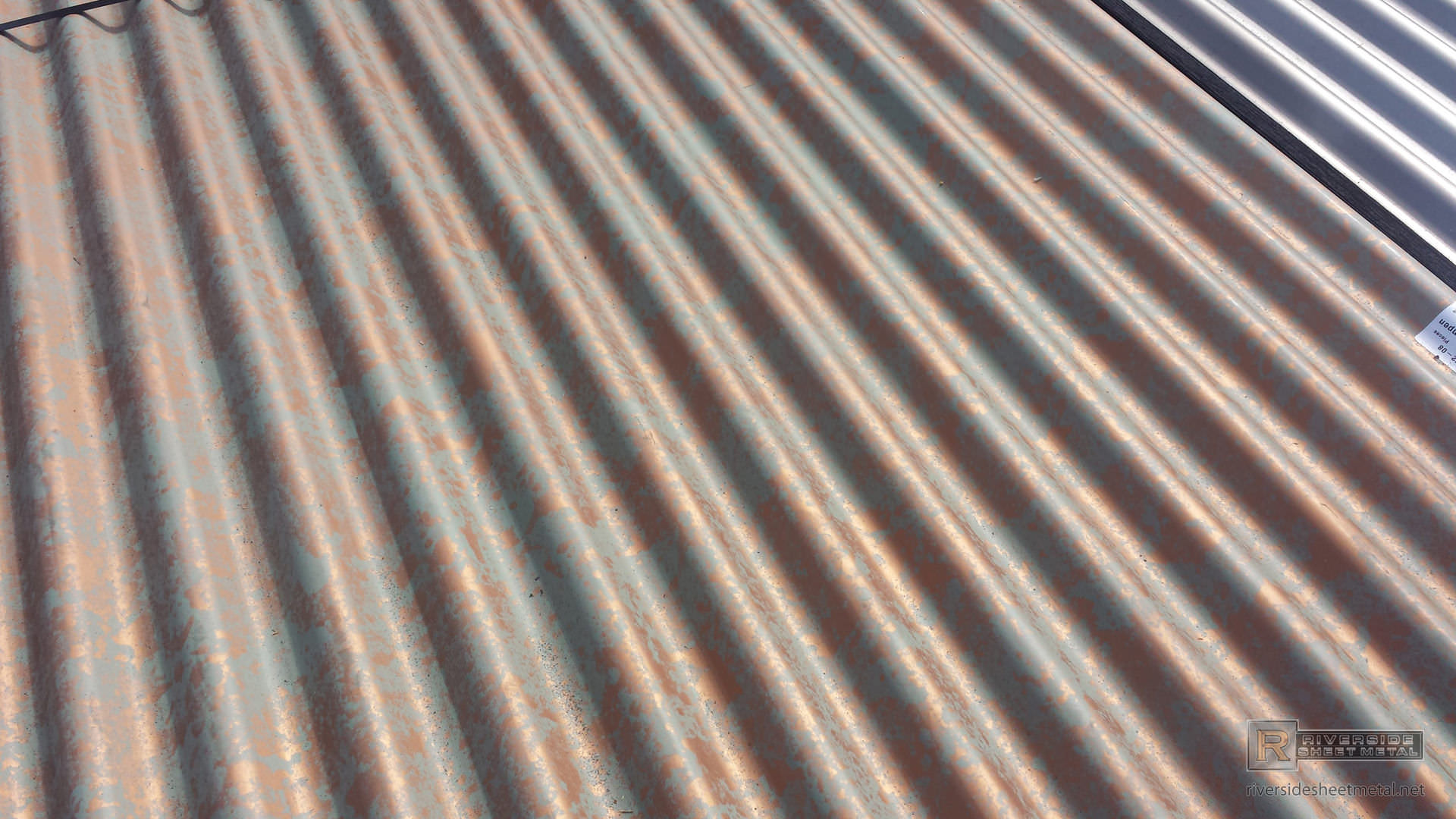

#CORRUGATED ROOFING FREE#

Corrugated Roofing Profileīushbury Cladding Ltd offer a free cutting service for our roofing sheets, allowing us to supply materials designed to completely meet your requirements. The roofing design & style is perfect for use on agricultural buildings, domestic premises, fencings, temporary roofs and much more. Benefit from having your corrugated roof sheets cut to any length up to 6m.Īt Bushbury Cladding Ltd, we can also provide you with flashings to match your sheet colour and fixings with colour-coded caps. Our corrugated metal products are available with a thickness or gauge of 0.5mm and 0.7mm and are available in a variety of finishes. We can meet your corrugated metal demands for anything from the smallest of jobs to the biggest of projects, so please do not hesitate to ask us how we can help with your next project. We also understand that jobs will vary in size and requirements, which is why we offer no minimum order or surcharge when you are ordering.

#CORRUGATED ROOFING INSTALL#

#CORRUGATED ROOFING MANUAL#

refer to Stramit® Top Hat & Battens Product Technical Manual for more information.įor more specific applications Stramit® Corrugated cladding must be designed to the pressure and foot traffic limits indicated. Where thinner supports are used, fastener capacity must be checked. Values are only valid for use with steel members of 1.5mm or thicker. FS, PS, NS - Full, partial and no shielding. Internal spans must have both end spans 20% shorter. *Where roof pitch is less than 10 degrees, use spans given in red italics for roof corners. Data should only be used for buildings 7m or less in height, 1000m 2 or less in area and unaffected by land topography.

Where the two standards differ, the worst case has been taken for each classification. Pressures are based on AS4055 or AS1170.2. The spans shown below take account of normal foot traffic and wind resistance including local pressure zone effects. NOTE: 0.60mm G300 Corrugated has a 300MPa steel grade.Ĭlass 4 fasteners should be used <1km from the coast.Ī NATSPEC work section is available for this product. All debris (nuts, screws, cuttings, filings etc.) shall be cleaned off daily. Repair minor blemishes with touch-up paint supplied by the roof manufacturer.

All sheeting shall be fixed in a workman-like manner, leaving the job clean and weathertight. Flashings shall be supplied in compatible materials as specified minimum cover of flashing shall be 150mm. Sheets shall be laid in such a manner that the approved side lap faces away from the prevailing weather.Ī minimum of 50mm shall be provided for projection into gutters. Suitable fixing screws in accordance with Australian Standard AS3566, Class 3, shall be used at every support with side lap fasteners installed at mid span if required. The sheeting shall be fixed to the purlins/girts in accordance with the manufacturer’s recommendations. Sheeting material shall be protected steel sheet to Australian Standard AS1397, with a minimum yield stress of 550MPa (Grade G550) and an AM100/AZ150 coating with or without an oven-baked paint film of selected colour, or a plain AM125/AZ150 coating. The roofing/walling shall be 0.42 (or 0.48) mm BMT Stramit ® Corrugated Roof and Wall Cladding in continuous lengths with sinusoidal ribs 16mm high, spaced at 76.2mm centres in accordance with AS1445.

0 kommentar(er)

0 kommentar(er)